Case Study MHE Safety System

HACKLAB’s unique modular AIoT based SAFFR™ MHE SAFETY SYSTEMS

At A

Glance

Challenges Faced

Benefits Reaped by SAFFR™ Devices

- Only authorised operator is driving the MHE

- Get all the real time working hour data of machine

- Safety heat map of plant for MHE's movement

- Ensuring speed violator operator

- Location Tracking of machine

- Speed Limit Compliance of MHE's

- Ensure Authorized operator only operate

- Running Hour & Idle time calculation

- Machine and Operator Profiling

Objectives

This case study shows implementation of IoT and AI based Hacklab's solutions help Hindalco Taloja plant to acahieve authorised operators access to the MHE's and get to know the productivity of machines.

Solutions

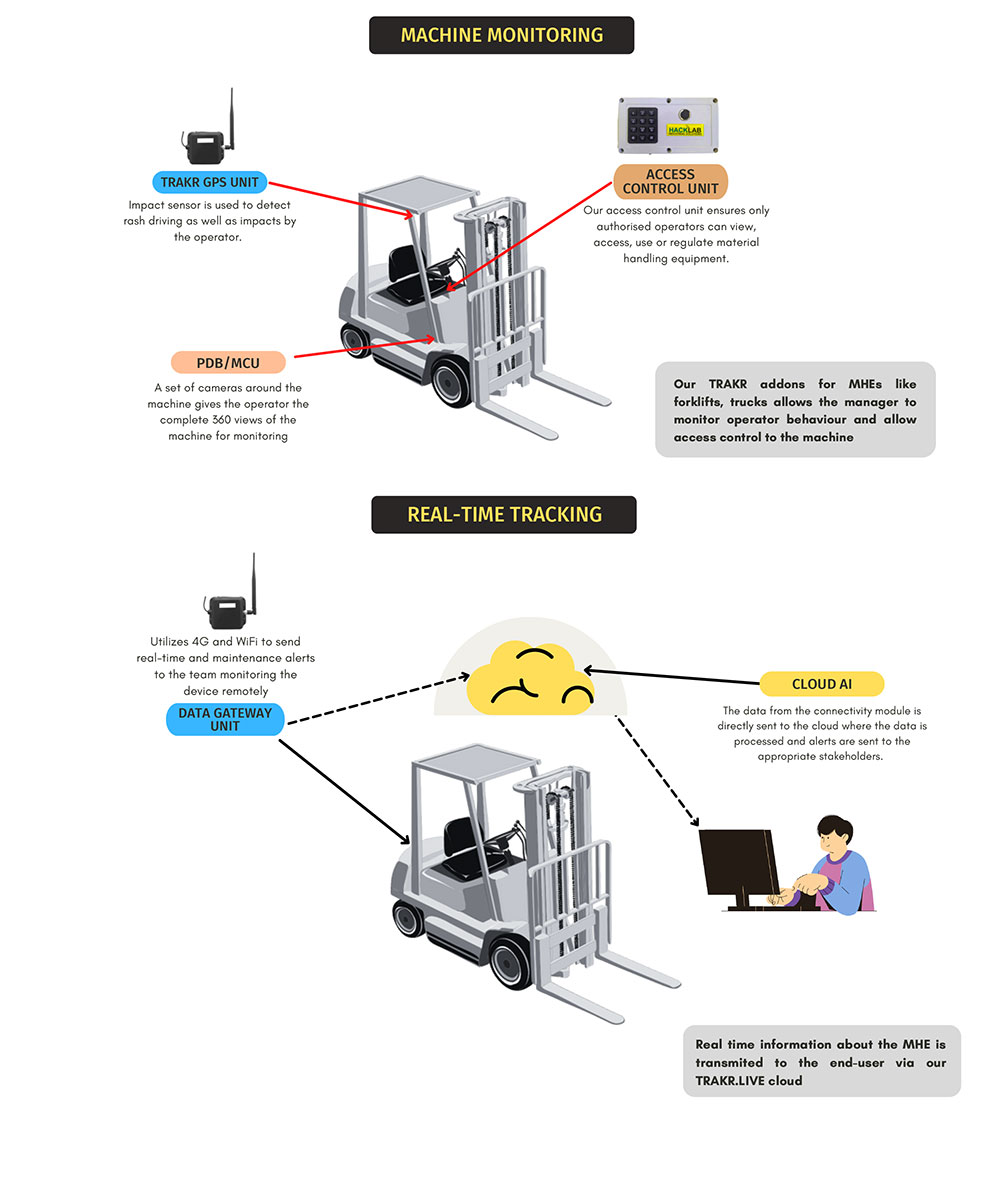

We had installed state of the art developed IoT and AI based following hardware on the machines to achieve the desired results

PDB- Master Control Unit

Bio metric Access Control Unit

TRAKR GPS Unit

CAN Logger Unit

Connectivity Module Unit

What Our ALOT Unit's Do ?

PDB- Master Control Unit

PDB/MCU analyse all the data's, information and inputs from various sensors and takes the desired action to ensure the safety and alerting the operator.

Biometric Access Control Unit

This unit have three types of access control systems i.e Keypad, RFID and Biometric to ensure only authorised and trained operator is driving the vehicle which helps us in reducing the chances of accidents by 90%.

TRAKR GPS Unit

TRAKR GPS Unit helps us in mapping the safety heat map of MHE movement area which helps us in knowing the frequent region of plant majority of violations are happening also get to know the over speeding of machines.

DATA Logger Unit

CAN Logger keeps the records of all the events happening with machine.

DATA Gateway Unit

This unit sends all the CAN Logger's recorded data to cloud for analysis and make its visibility possible to dashboard and for daily MHE productivity report.